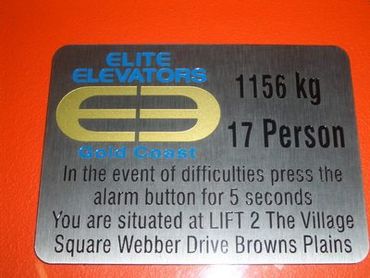

Metal etching

.jpeg/:/rs=w:370,cg:true,m)

.jpeg/:/rs=w:370,cg:true,m)

Information

Metal etching, also known as metal engraving or metal etching, is a process that involves removing material from a metal surface to create a design, pattern, or text. It is a technique used to achieve intricate and precise details on metal objects. Metal etching can be done using various methods, including chemical etching, laser etching, and mechanical etching.

Here are some key points about metal etching:

- Chemical Etching: Chemical etching is a common method used for metal etching. It involves using chemicals to selectively remove layers of metal from the surface. The process typically involves applying a mask or resist material on the metal, exposing the desired design or pattern, and then immersing the metal in an etching solution that dissolves the unprotected areas.

- Laser Etching: Laser etching, also known as laser engraving, is another popular method for metal etching. It involves using a laser beam to remove material from the metal surface. The laser beam is precisely controlled to vaporize or melt the metal, creating the desired design or text. Laser etching offers high precision and can be used on a variety of metals.

- Mechanical Etching: Mechanical etching, also called traditional engraving, involves physically cutting or scraping the metal surface to create the desired design. This method is often performed using specialized tools, such as gravers or rotary engraving machines. Mechanical etching requires skilled craftsmanship and is commonly used for artistic or decorative purposes.

- Applications: Metal etching finds applications in various industries and sectors. It is commonly used for creating designs and logos on jewelry, trophies, plaques, nameplates, signage, and other metal-based products. It is also used in the manufacturing of printed circuit boards (PCBs), where chemical etching is used to create circuit patterns on metal substrates.

- Material Compatibility: Metal etching can be performed on a wide range of metals, including stainless steel, aluminum, brass, copper, bronze, and titanium. The choice of metal depends on the desired aesthetics, durability, and functionality of the final product.

- Precision and Detail: Metal etching allows for precise control over the design and depth of the etched area, enabling intricate details and fine lines to be achieved. This makes it suitable for creating complex patterns, textures, or even reproducing artworks on metal surfaces.

- Customization and Personalization: Metal etching offers the advantage of customization and personalization. It allows for unique designs, logos, or text to be etched onto metal objects, providing a way to add a personalized touch or brand identity to products.

- Surface Finish: Metal etching can produce different surface finishes, depending on the desired effect. It can create a matte, brushed, or polished appearance on the etched areas, enhancing the visual appeal of the metal object.

Metal etching is a versatile technique that combines craftsmanship and technology to create intricate and customized designs on metal surfaces. Whether for decorative purposes, branding, or functional applications, metal etching provides a method to achieve high-quality and precise results on various metal objects.

Call or email Ph: 07 3208 4389 email: info@tecgraph.com.au to confirm your requirements

Copyright © 2023 Tecgraph - All Rights Reserved.

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.